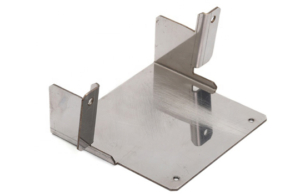

Custom Metal Stamping

Custom Sheet Metal Stamping Parts of All Sizes

Fortuna can produce high precision, custom sheet metal stampings and components that meet all customer design specifications.

Utilizing stamping presses with capacities up to 250 tons and precision stamping dies and tooling that we make in-house. We serve customers across all industries and deliver short- to medium-run metal stampings and sheet metal prototyping for parts and components of all sizes and shapes.

Sheet Metal Fabrication & Precision Metal Stamping Capabilities

Our full-service custom sheet metal stamping and fabrication shop offers the full spectrum of metal stamping options such as:

- Blanking: A fabrication process where a punch and die are used to cut pieces, referred to as blanks, from sheet metal for further processing. It produces minimal burrs, which helps reduce finishing costs and lead time.

- Piercing: Uses similar machinery as blanking and involves using a punch and die to create holes, slots, and notches in sheet metal. It creates tight tolerances, produces a cleaner cut than drilling, and is more productive than laser cutting.

- Forming: Includes different processes where force is applied to sheet metal to modify its geometry and create thin, flat pieces that can then be formed into more complex shapes.

- Drawing: A process where tensile force is used to stretch, or draw, sheet metal blanks over a die until the desired thickness and shape is achieved. This precision metal stamping process is used to create fluid handling, aircraft parts, electronic components, and more.

We have small punch presses for small precision metal stampings, along with large punch presses for more complex custom metal stamping projects. Our metal stamping professionals are trained extensively in the metal stamping industry. Contact us today to learn more about our custom sheet metal stamping capabilities.

Custom Sheet Metal Stamping Materials

We work with a wide range of custom sheet metal stamping materials. If you don’t see your preferred material option listed below, contact us to discuss your project’s specific requirements.

- Cold Rolled Steel

- Stainless Steel

- Aluminum

- Galvanized Steel

- Beryllium Copper

- Brass

- Phosphor bronze

- Nickel Silver

Custom-Made Precision Metal Stamping Dies

Stamping dies are custom-made tools that are used with a stamping press to cut or form sheet metal into the desired shape. In most cases, every stamping tool is made specifically for the project at hand. Stamping dies are typically manufactured from tool steel, which is hard enough to cut most other types of metal while maintaining the tolerances the stamped part requires.

Fortuna stamping dies are made by our in-house tool. All the tooling spare parts we applied are from MISUMI and the Seibu CNC machines to process the tooling is imported from Japan also. We have the confidence to produce the products with the tooling over many years and we won’t charge any extra tooling fees. Quality always is the first priority of the precision parts.

Sheet Metal Prototyping Services

Our rapid sheet metal stamping capabilities are ideal for metal prototype fabrication. We will work with you to develop prototypes and samples that enable you to test your part designs for proper fit, form, and function. Sheet metal prototyping helps ensure precision and on-time deliveries while reducing overall project costs.

Additional Sheet Metal Fabrication Services

In addition to custom metal stamping, we offer a range of other sheet metal fabrication services to give our customers high precision parts, components, and assemblies that match their application requirements. We provide laser cutting, bending, welding, secondary finish, and more.